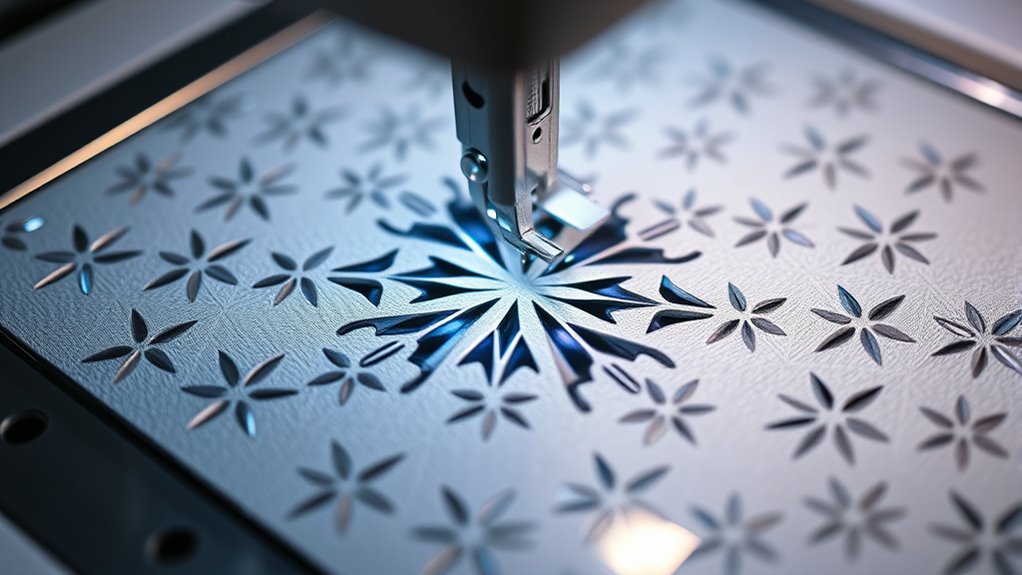

WDT 2.0 introduces advanced needle patterns that help you eliminate clumping and achieve seamless, professional finishes. Its innovative algorithms adjust needle movements dynamically, ensuring even stitches across various fabric types. By using precise tension control and versatile patterns, you can create intricate designs without worries about fiber stress or uneven textures. If you want to discover how these cutting-edge techniques can elevate your textile projects, you’ll find more insights ahead.

Key Takeaways

- WDT 2.0 uses adaptive needle patterns that optimize stitch formation, reducing fiber stress and preventing clumping.

- The system’s intelligent algorithms adjust needle movements in real-time to maintain consistent tension and avoid fabric bunching.

- Precise control over stitch density and pattern variation ensures even fabric texture, minimizing the risk of clumps.

- Seamless tension calibration and automatic adjustments help achieve clean, professional finishes without thread clumping.

- Versatile needle techniques and pattern customization in WDT 2.0 enhance durability and eliminate the formation of unwanted lumps.

The Evolution of Textile Technology and WDT 2.0

The evolution of textile technology has continually pushed the boundaries of precision and efficiency, leading to breakthroughs like WDT 2.0. Over the years, textile innovation has transformed manufacturing processes, making them faster, more accurate, and capable of producing higher-quality fabrics. Manufacturing advancements enable machines to handle complex patterns with minimal waste and defects, setting new standards for the industry. WDT 2.0 exemplifies this progress, incorporating cutting-edge needle patterns that reduce clumping and improve stitch consistency. As technology advances, you benefit from these innovations through more reliable production, enhanced fabric quality, and greater customization options. This ongoing evolution reflects the industry’s commitment to refining textiles, ensuring your products are more precise and efficient than ever before.

Key Features of WDT 2.0 and Its Innovative Design

Building on the advancements in textile technology, WDT 2.0 introduces a range of innovative features designed to optimize stitching performance. Its key features include adaptive needle patterns that enhance fabric durability by reducing stress on fibers, allowing for longer-lasting garments. The design also focuses on increasing stitch density uniformly across various fabrics, ensuring consistent quality without clumping. WDT 2.0’s intelligent algorithms adjust needle movement in real-time, minimizing fabric puckering and thread breakage. The system’s intuitive interface provides precise control over stitch parameters, enabling you to customize settings for different materials. Additionally, color accuracy plays a crucial role in achieving consistent stitch visibility and quality in various lighting conditions. Overall, these features work together to deliver durable, high-quality stitches, improve efficiency, and prevent common sewing issues associated with inconsistent stitch formation.

How WDT 2.0 Achieves Seamless Finishes and Reduces Waste

With WDT 2.0, you’ll notice how precise stitch alignment creates smooth, professional finishes every time. It also minimizes material waste by optimizing needle patterns, so you get the most out of each fabric. This combination helps you save time and resources while achieving flawless results. Additionally, understanding merchant service risks can help you protect your investment in new technology.

Precise Stitch Alignment

Achieving perfect stitch alignment is essential for seamless finishes and minimizing material waste, and WDT 2.0 makes this easier than ever. Its advanced needle patterns automatically adjust thread tension to match fabric compatibility, ensuring consistent stitch placement. When thread tension is calibrated correctly, stitches stay aligned, reducing puckering and uneven seams. WDT 2.0’s precise control system detects fabric types and adapts the stitching pattern accordingly, preventing misalignment caused by incompatible materials. This level of precision guarantees a professional finish, with stitches perfectly aligned across different fabrics. As a result, you spend less time reworking seams and more time focusing on your project. With WDT 2.0, achieving flawless stitch alignment becomes effortless, delivering cleaner, more durable results every time.

Material Waste Minimization

By automatically adjusting stitch tension based on fabric type and thickness, WDT 2.0 minimizes material waste and guarantees seamless finishes. Proper thread tension enhances fabric durability by preventing puckering or fraying, reducing the need for rework. This precision reduces excess material use, optimizing fabric consumption.

| Fabric Type | Recommended Thread Tension | Result |

|---|---|---|

| Lightweight | Moderate | Smooth, minimal waste |

| Heavyweight | Higher | Strong seam, less rework |

| Stretch Fabrics | Adjusted for elasticity | Durable, waste-efficient |

This intelligent adjustment ensures your stitches are perfect, reducing scraps and conserving resources, while maintaining high-quality finishes.

Exploring the Range of Intricate Needle Patterns

You can explore a variety of pattern styles that add unique textures to your work. Trying out different technique variations opens up new creative design possibilities. With these options, you’ll find endless ways to personalize your projects and achieve intricate, professional-looking results.

Diverse Pattern Styles

Diverse needle pattern styles offer a rich variety of options to enhance your quilting projects, allowing for intricate designs that add depth and texture. You can experiment with patterns that emphasize fabric texture, creating visual interest through varied stitch densities and shapes. To achieve clean, precise designs, pay close attention to thread tension, adjusting it as needed for different patterns. Some styles might require tighter tension for sharp lines, while others benefit from looser settings for softer, flowing effects. By exploring a range of patterns, you can tailor your quilting to match your fabric’s characteristics and your creative vision. This versatility helps you avoid clumping and ensures each stitch contributes meaningfully to your overall design, elevating your quilting craftsmanship. Proper tension control is essential for achieving professional-looking results in diverse needle pattern styles.

Technique Variations Explored

Exploring different needle pattern techniques opens up a world of possibilities for creating intricate, eye-catching designs. By experimenting with embroidery techniques, you can develop complex textures and layered effects that elevate your textile design. Variations such as satin stitches, French knots, and chain stitches allow you to add depth and detail to your work. Consider this visual guide to inspire your creativity: textile embellishments.

| Technique | Effect | Best Use |

|---|---|---|

| Satin Stitch | Smooth, sleek fills | Outlining or filling areas |

| French Knot | Textured, raised dots | Embellishments, accents |

| Chain Stitch | Continuous, decorative lines | Borders, intricate patterns |

These technique variations enable you to diversify your embroidery techniques and push your textile design skills further.

Creative Design Possibilities

By combining various needle techniques, you can craft a stunning array of intricate patterns that bring your textile designs to life. These techniques enable you to explore creative possibilities, resulting in unique motifs that enhance fabric durability and visual appeal. Intricate needle patterns allow for seamless color blending, creating smooth progressions and vibrant gradients that elevate your work. With precise control, you can incorporate complex details without sacrificing fabric strength, ensuring your designs remain resilient over time. The versatility of advanced needle patterns empowers you to experiment with textures and layers, opening endless avenues for artistic expression. Ultimately, this approach helps you produce eye-catching, durable textiles that showcase your craftsmanship and push the boundaries of traditional needlework.

Benefits for Professional Tailors and Hobbyists Alike

Whether you’re a professional tailor or a hobbyist, WDT 2.0 offers significant advantages that make sewing more efficient and precise. It enhances your control over thread tension, ensuring consistent stitches across various fabric types. Additionally, WDT 2.0’s advanced needle patterns improve fabric compatibility, allowing you to work seamlessly with delicate silks or heavy denim without clumping or skipped stitches. The following table highlights these benefits:

| Benefit | Explanation |

|---|---|

| Improved thread tension | Ensures even stitches regardless of fabric thickness |

| Better fabric compatibility | Works well with a wide range of materials |

| Faster adjustments | Less need to manually tweak tension settings |

| Consistent stitch quality | Maintains uniformity throughout the project |

| Reduced clumping | Keeps stitches neat and professional-looking |

In addition, understanding the advanced needle patterns used in WDT 2.0 can further optimize your sewing outcomes.

Step-by-Step Guide to Implementing WDT 2.0 in Your Projects

To successfully implement WDT 2.0 in your projects, start by preparing your sewing machine and materials. Begin with fabric tension adjustments to ensure even stitching, which is vital for smooth needle patterns. Next, select the right thread compatibility; choose threads that match your fabric and pattern needs for ideal results. Install the appropriate needle and set your machine to a moderate stitch length. Practice on scrap fabric to fine-tune tension settings and verify that the needle moves smoothly without clumping or skipped stitches. Follow the WDT 2.0 pattern instructions carefully, maintaining consistent fabric tension throughout. Adjust as needed during the process to prevent issues. Staying attentive to thread compatibility and tension control will help you achieve clean, clump-free needle patterns in your projects. Attention to detail is crucial for identifying and resolving issues early, ensuring your sewing quality remains high.

Comparing WDT 2.0 With Traditional Needle Pattern Systems

WDT 2.0 introduces significant improvements over traditional needle pattern systems, offering a more reliable and consistent stitching experience. Unlike older systems, WDT 2.0 better manages thread tension, reducing clumps and uneven stitches. It’s also compatible with a wider range of needles, enhancing flexibility in your projects. Traditional systems often struggle with thread tension adjustments, leading to inconsistent results. WDT 2.0 simplifies this by automatically balancing tension, ensuring uniformity. Here’s a quick comparison: Resources and Tools make it easier to understand the benefits of advanced systems like WDT 2.0.

| Feature | WDT 2.0 | Traditional Systems |

|---|---|---|

| Thread Tension Control | Automatic, precise | Manual, often inconsistent |

| Needle Compatibility | Wide range | Limited to specific needles |

| Clump Prevention | Zero clumps | Frequent clumping |

| Stitch Consistency | High | Variable |

| Ease of Use | User-friendly | More complex |

Future Prospects and Developments in Needle Pattern Technology

Advancements in needle pattern technology are poised to revolutionize sewing by integrating smarter, more adaptive systems. With AI integration, future needle patterns will learn from your stitching habits, improving precision and reducing errors. Expect innovations in sustainable materials, making sewing more eco-friendly without sacrificing quality. These developments will enable you to customize patterns dynamically, optimizing for fabric type and project needs. Here are four key prospects:

- AI-powered pattern adjustments for flawless results.

- Use of biodegradable and recycled materials.

- Real-time feedback for pattern optimization.

- Automated pattern generation tailored to specific fabrics.

These trends will make sewing faster, cleaner, and more sustainable, empowering you to achieve professional results with less effort. As technology progresses, your sewing experience will become more intuitive and environmentally conscious.

Frequently Asked Questions

Can WDT 2.0 Be Integrated With Existing Sewing Machine Models?

You might wonder if WDT 2.0 can be integrated with your existing sewing machine models. Compatibility concerns often arise, and you may face integration challenges, especially with older or specialized machines. To guarantee smooth setup, check WDT 2.0’s compatibility specifications and consult your machine’s manufacturer. Properly addressing these concerns helps you avoid issues and fully utilize WDT 2.0’s advanced needle patterns for perfect stitching.

What Materials Are Compatible With WDT 2.0 Needle Patterns?

You wonder about compatibility fabrics and needle types. WDT 2.0 works best with a variety of fabrics, from lightweight silks to heavier denim, ensuring versatility. The key is selecting the right needle type—whether sharp, ballpoint, or universal—to match your fabric. This combination guarantees smooth stitching and ideal pattern execution, allowing you to achieve precise, clump-free results across different materials.

How Does WDT 2.0 Impact Production Speed and Efficiency?

You’ll find that WDT 2.0 notably boosts production speed and efficiency through automation integration. It streamlines workflows, reducing manual interventions, and guarantees quality consistency across your output. By minimizing clumping and errors, it allows you to produce more in less time, enhancing overall productivity. The system’s advanced needle patterns help maintain uniform results, making your process faster and more reliable without sacrificing quality or precision.

Are There Specific Maintenance Requirements for WDT 2.0 Technology?

Ever wondered if your equipment needs special care? With WDT 2.0, you’ll want to stay on top of needle pattern maintenance to prevent clogs and guarantee smooth operation. Regularly check machine compatibility and clean components as recommended by the manufacturer. Do you really want to risk downtime? Proper maintenance keeps your system running efficiently, saves you money, and prolongs its lifespan, making your production process seamless.

Is WDT 2.0 Suitable for Both Industrial and Home Sewing Applications?

You might wonder if WDT 2.0 suits both industrial and home sewing. It’s designed for fabric compatibility across various materials, making it versatile for different projects. Plus, its intuitive features enhance user accessibility, so you can operate it comfortably whether you’re a beginner or an expert. Its adaptability guarantees you get consistent results, whether you’re working on complex industrial tasks or simple home sewing projects.

Conclusion

So, there you have it—WDT 2.0, the miracle solution that promises zero clumps and flawless finishes. Sure, it’ll save you time, reduce waste, and make you look like a sewing genius overnight. But remember, even with all this tech, perfection’s just a needle’s prick away from disaster. Embrace the future, or stick to your old patterns—either way, your sewing destiny awaits!