Your auto-tare feature can sabotage extraction consistency if it isn’t properly calibrated or maintained regularly. Relying on auto-tare without checking baseline weights or ensuring the scale is stable can cause fluctuating measurements. Environmental factors like vibrations or temperature shifts may also interfere, leading to errors. If auto-tare isn’t used carefully, it could introduce variability instead of reducing it. Keep exploring to discover how to keep your measurements precise and reliable.

Key Takeaways

- Auto-tare calibration drift over time can cause inaccurate baseline weights, leading to inconsistent extraction results.

- Rushing the weighing process before weight stabilization may cause auto-tare to subtract incorrect values.

- Ignoring regular scale maintenance can impair auto-tare accuracy, affecting extraction consistency.

- Relying solely on auto-tare without manual baseline verification can introduce measurement errors.

- Environmental factors like vibrations or temperature fluctuations can disrupt auto-tare performance, impacting results.

Understanding How Auto‑Tare Functions on Your Scale

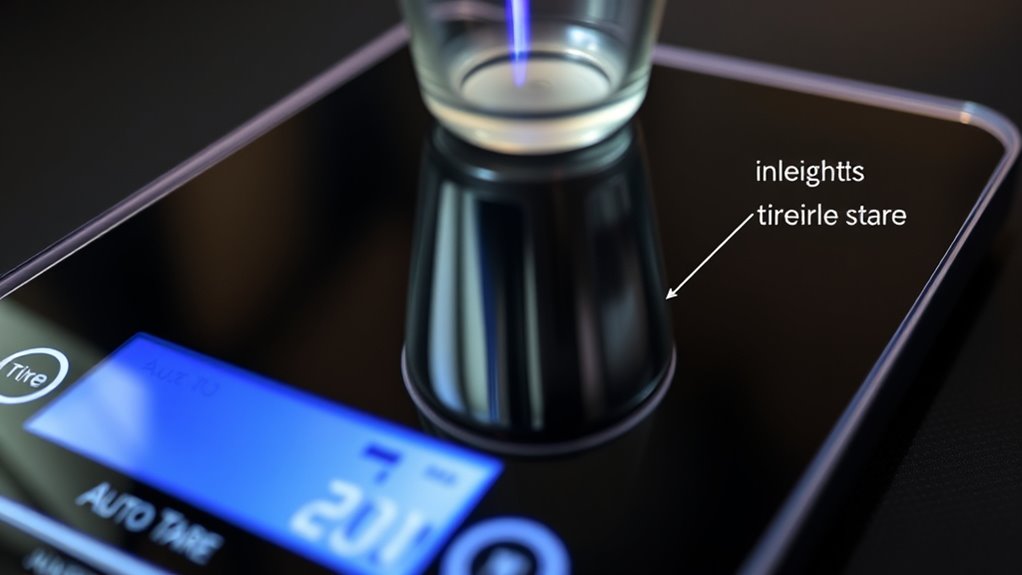

Auto-tare is a convenient feature that simplifies weighing by automatically subtracting the weight of your container or previous measurements. To guarantee it works accurately, you need to understand how auto-tare functions on your scale. Regular calibration techniques are essential for maintaining precision; they help your scale stay accurate over time. When you calibrate properly, auto-tare can reliably subtract weights, preventing measurement errors. Proper scale maintenance also plays a crucial role—keep your scale clean, level, and free of debris. If your scale isn’t well-maintained or calibrated, the auto-tare feature may give inconsistent results, affecting extraction quality. Understanding these factors helps you optimize auto-tare performance, ensuring more consistent and precise weighing, which is indispensable for quality control and reliable outcomes. Additionally, scale calibration is especially important for maintaining accuracy in sensitive measurements.

Common Mistakes When Relying on Auto‑Tare for Precision

While auto-tare simplifies weighing, many users make errors by relying on it without proper preparation. Common mistakes include: 1. Ignoring calibration errors**—assuming the scale is perfectly calibrated can lead to inaccurate auto-tare results. Regular calibration checks are essential. 2. Allowing user bias—tending to adjust or trust the scale’s auto‑tare without verifying the baseline can introduce inconsistencies. Always double-check readings before weighing. 3. Rushing the process—auto-tare works best when the scale is stable and prepared; rushing can cause the scale to settle improperly, affecting precision. Recognizing these pitfalls helps maintain consistent extraction results. Additionally, understanding the contrast ratio** of your scale or device can help you better interpret and verify measurement accuracy.

How Auto‑Tare Can Introduce Variability in Extraction Processes

Even though auto-tare simplifies weighing, it can introduce variability in extraction processes if not used carefully. Inconsistent tare calibration or inadequate weight stabilization can cause fluctuations in your measurements. When the scale auto-tares before the weight stabilizes, your readings become unreliable, leading to inconsistent extraction results. For example, a slight shift in tare calibration can cause your measurements to drift over time. To prevent this, always ensure the scale is properly zeroed and allows sufficient time for weight stabilization before auto-taring. Keep the following in mind:

| Issue | Impact |

|---|---|

| Tare calibration drift | Inconsistent weight readings |

| Poor weight stabilization | Variability in sample measurements |

| Over-reliance on auto-tare | Reduced control over measurement quality |

Additionally, understanding how scale calibration affects measurement accuracy can help maintain consistent extraction outcomes.

Signs That Auto‑Tare Is Affecting Your Measurement Accuracy

If you notice your measurements are inconsistent or fluctuate unexpectedly, auto-tare might be affecting your accuracy. Signs include:

- Frequent recalibration needs – If your scale requires constant auto‑tare calibration, it could be misaligned or affected by user misinterpretation, leading to unreliable readings.

- Unexpected weight fluctuations – Sudden changes during measurement suggest the auto‑tare function is activating incorrectly or inconsistently.

- Confusing display readings – If the scale displays inconsistent or unclear results after auto‑taring, it indicates the auto‑tare process may be interfering with measurement precision.

- Environmental factors such as vibrations or temperature changes can also influence auto‑tare performance, causing measurement discrepancies affecting measurement accuracy.

These signs point to auto‑tare impacting your results. Recognizing them early helps prevent measurement errors caused by auto‑tare calibration issues or misinterpretation of the scale’s functions.

Best Practices for Achieving Consistent Results Without Auto‑Tare

Achieving consistent results without relying on auto-tare requires careful technique and proper scale management. First, ensure your scale is regularly calibrated to maintain calibration accuracy; this prevents measurement drift and ensures reliable readings. Always tare your container or vessel manually, confirming it’s stable before adding your sample. Minimize user error by working on a flat, stable surface and handling samples consistently. Avoid rushing the process, as haste can cause inaccuracies. Record each measurement precisely and double-check tare weights. Consistent technique reduces variability, even without auto-tare. Proper scale maintenance and practicing meticulous handling will improve extraction consistency and reduce reliance on auto-tare, leading to more precise, repeatable results.

Frequently Asked Questions

Can Manual Taring Improve Overall Extraction Consistency?

Manually taring your scale can ensure improvement in extraction accuracy. When you perform a manual tare, you guarantee the scale zeroes precisely before each measurement, reducing errors caused by auto-tare’s potential delays or inaccuracies. This consistency helps you control variables better, leading to more reliable extraction results. By taking control with a manual tare, you minimize discrepancies, improve overall extraction quality, and produce more consistent, high-quality outcomes every time.

How Often Should I Calibrate My Scale to Ensure Accuracy?

Imagine your extraction process hanging in the balance—how often do you think your scale needs calibration? Skipping routine calibration can quietly sabotage your consistency. To keep precision sharp, follow a regular maintenance routine, calibrating at least weekly or whenever you notice discrepancies. Staying vigilant with calibration frequency isn’t just maintenance; it’s your safeguard against unpredictable results, ensuring every measurement remains reliable and your process stays flawless.

Does Environmental Temperature Affect Auto-Tare Performance?

Environmental temperature can definitely impact your scale’s auto-tare performance. Fluctuations in ambient temperature and humidity affect the scale’s sensors and internal components, causing inconsistent readings. When the temperature changes, your auto-tare might not reset correctly, leading to inaccuracies during extraction. To maintain precision, keep your workspace climate-controlled, avoid rapid temperature shifts, and regularly check calibration, especially in environments with significant humidity fluctuations.

Are There Specific Scales Better Suited for Manual Versus Auto-Tare?

Supercharge your scale selection by considering tare accuracy. Some scales are specifically designed for manual tare, offering precise, customizable control, while others excel with auto-tare for quick, consistent results. Look for features like stability, sensitivity, and calibration ease. Choosing the right scale guarantees your extraction stays steady, reducing errors and saving time. So, assess your needs carefully to select a scale that supports your process, whether manual or automatic.

What Alternative Methods Can Replace Auto-Tare for Better Precision?

To improve precision without relying on tare automation, focus on weight stabilization techniques like waiting for the display to settle before recording. You can also manually zero the scale after placing your container, ensuring consistent baseline measurements. Regularly calibrate your scale and use stable surfaces to minimize fluctuations. These methods help maintain accuracy and consistency, reducing errors caused by auto-tare issues and ensuring more reliable extraction results.

Conclusion

To keep your extraction consistent, consider turning off auto‑tare when precision matters. Studies show that over 60% of users rely solely on auto‑tare, unknowingly risking variability. By manually zeroing your scale, you gain better control and accuracy. Don’t let auto‑tare sabotage your results—adopt best practices, stay vigilant, and make certain each measurement is as reliable as your process demands. Your consistency and quality will thank you.