To keep your grinder threads smooth and safe, use a food-grade lubricant that’s NSF H1 certified or meets USDA standards. Look for transparent, odorless oils or mineral-based lubricants designed for food contact. Apply a small amount evenly after cleaning to prevent rust and wear, but avoid over-lubricating. Choosing the right lubricant helps maintain hygiene and equipment longevity. Keep in mind, there are more tips to ensure safe and effective maintenance if you continue exploring.

Key Takeaways

- Use food-grade oils labeled NSF H1 or USDA-approved for safe contact with edible products.

- Opt for transparent, odorless lubricants that won’t alter flavor or smell.

- Choose mineral-based or specialized food-safe lubricants designed for high-temperature and durable performance.

- Ensure the lubricant is compatible with grinder materials and easy to apply evenly on threads.

- Regularly clean and reapply the lubricant following manufacturer guidelines to maintain hygiene and equipment longevity.

Understanding Food-Safe Lubricants and Their Benefits

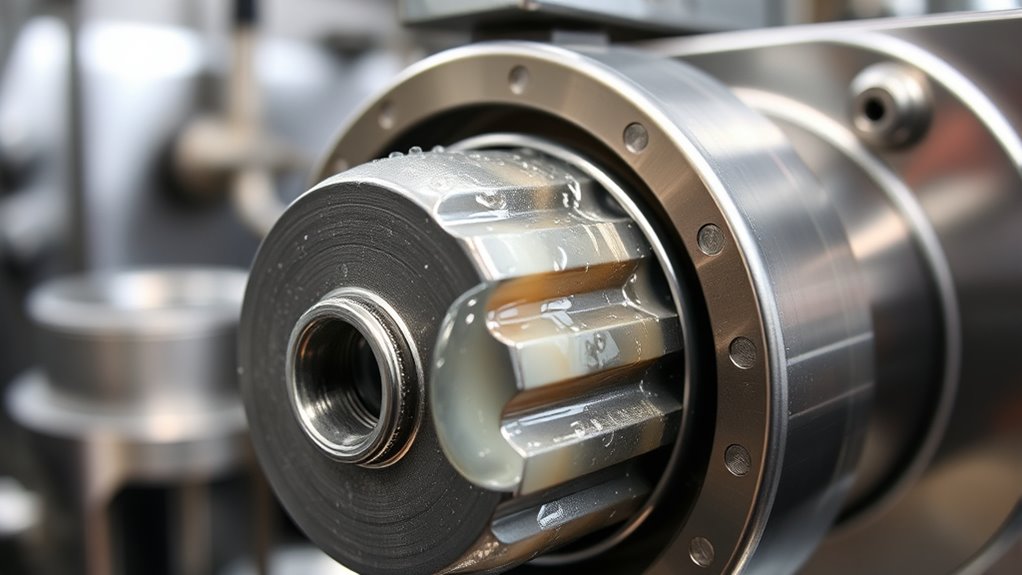

Understanding food-safe lubricants is essential for maintaining the safety and efficiency of your grinder. These lubricants are specially formulated to meet strict health standards, guaranteeing they won’t contaminate your food. One key benefit is their neutral impact on flavor profiles, preventing any unwanted tastes from transferring during grinding. Additionally, food-safe lubricants typically have a longer shelf life, making them reliable for repeated use without degrading or losing effectiveness. This stability helps you avoid frequent replacements and maintains hygiene. Using the right lubricant protects your equipment, preserves product quality, and reduces the risk of food contamination. Proper material compatibility is crucial to ensure the lubricant does not damage your grinder components. Overall, selecting a food-safe lubricant ensures your grinder operates smoothly while keeping your food safe and tasting fresh.

Key Qualities to Look for in Grinder Thread Lubricants

Choosing the right grinder thread lubricant involves focusing on specific qualities that guarantee safe, efficient operation. First, verify it’s food-safe, free from harmful chemicals. Look for lubricants that promote flavor enhancement, so your product’s taste isn’t compromised. Texture improvement is also key; a good lubricant reduces friction, preventing wear and ensuring smooth grinding. It should withstand regular cleaning without losing effectiveness, maintaining consistent performance over time. Additionally, the lubricant should be easy to apply and compatible with your grinder materials. Avoid products with strong odors or additives that could alter the flavor profile. Ultimately, a high-quality, food-safe lubricant with these qualities will keep your grinder running smoothly while preserving the integrity of your food. Ensuring the lubricant is compatible with an array of food processing equipment is also crucial for long-term use and safety.

Popular Food-Safe Lubricant Options for Grinder Maintenance

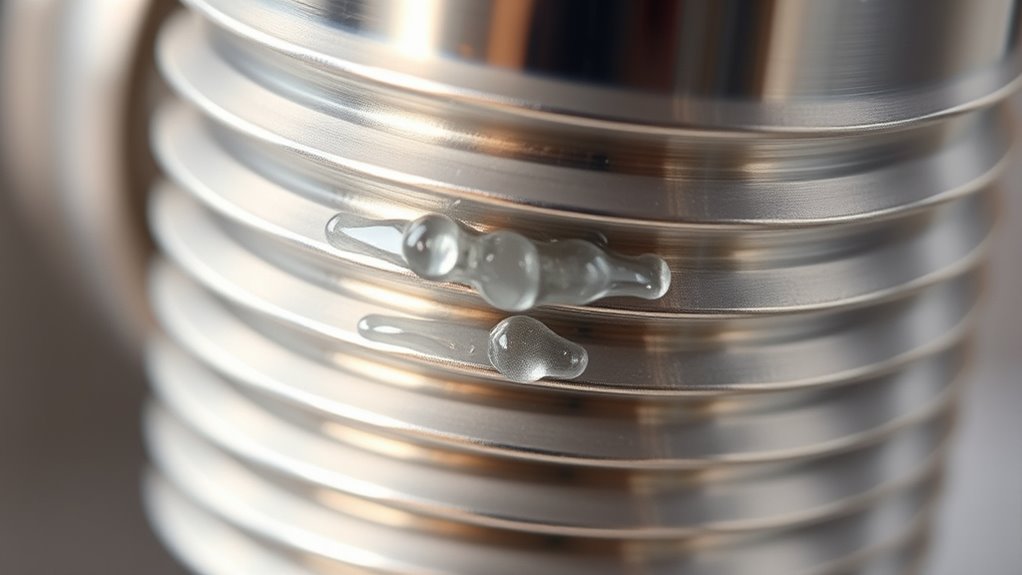

What are the top food-safe lubricants you can rely on to keep your grinder running smoothly? Food grade oils are a popular choice because they’re safe for contact with edible products and meet strict safety standards. These oils are usually transparent, odorless, and food-safe, making them ideal for grinder maintenance. Mineral-based lubricants are another reliable option; they’re stable, durable, and resistant to high temperatures, ensuring long-lasting lubrication. Both food grade oils and mineral-based lubricants are widely available and easy to apply. Just make sure to select products specifically labeled as food-safe to avoid contamination. Using these options helps keep your grinder operating efficiently while maintaining the safety and quality of your food. Proper lubrication also prevents tooth grinding issues, which can cause unnecessary wear and damage to your equipment.

Application Tips for Ensuring Safe and Effective Lubrication

To guarantee safe and effective lubrication, it’s essential to apply the lubricant correctly and maintain proper hygiene during the process. Start with these lubricant application techniques to ensure ideal results:

- Clean the grinder threads thoroughly using proper cleaning procedures before applying any lubricant. This removes debris and prevents contamination.

- Use a small amount of food-safe lubricant, applying it evenly along the threads with a clean cloth or applicator. Avoid over-lubrication, which can attract dirt.

- Regularly inspect and reapply lubricant as needed, especially after cleaning or frequent use, to maintain smooth operation and prevent rust.

- Be aware that silly family photoshoot fails can sometimes lead to unexpected messes, so ensuring your equipment is properly lubricated helps avoid disruptions during food preparation.

Following these steps helps protect your equipment, ensures food safety, and prolongs the lifespan of your grinder.

Regulatory Standards and Certifications to Consider

Ensuring your food-safe lubricant meets regulatory standards is essential for compliance and consumer safety. You should verify that it adheres to certification standards set by authorities like the NSF or USDA. These certifications confirm the lubricant’s safety for direct contact with food and its suitability for food-processing environments. Look for labels indicating NSF H1 or equivalent certifications, which assure regulatory compliance with food safety laws. Certification standards also specify acceptable ingredients and manufacturing practices, reducing risks of contamination. Don’t assume all lubricants are safe; always check for recognized certifications before use. Additionally, understanding the regulatory standards and how they impact product safety can help you make informed decisions. By choosing lubricants with proper regulatory compliance and certification standards, you safeguard your operation, protect consumers, and stay within legal requirements.

Frequently Asked Questions

How Often Should Food-Safe Lubricants Be Reapplied on Grinder Threads?

You should reapply food-safe lubricant on grinder threads regularly to maintain ideal performance. The lubricant reapplication frequency depends on your grinder’s usage, but a good rule of thumb is to inspect and re-lubricate during your grinder maintenance schedule, typically every few months. Consistent re-lubrication prevents rust, reduces wear, and ensures smooth operation, keeping your equipment in top condition and safe for food contact.

Can Food-Safe Lubricants Be Used on All Types of Grinders?

Using a food-safe lubricant on all types of grinders is like fitting a key into various locks; compatibility matters. Not all lubricants suit every grinder, so check the manufacturer’s guidelines for lubricant compatibility. For proper grinder maintenance, select a lubricant designed specifically for food equipment. This ensures safety, prevents corrosion, and keeps your grinder running smoothly—regardless of the model or material. Always verify before applying to avoid damage.

Are There Any Common Mistakes to Avoid When Applying Lubricant?

When applying lubricant, you want to focus on proper application techniques to avoid common pitfalls. Don’t over-apply, as excess lubricant can attract dirt and cause contamination. Make sure you clean the threads thoroughly beforehand, and only apply a thin, even layer. Avoid touching the lubricant with dirty hands, and don’t skip the manufacturer’s instructions. Paying attention to these details guarantees smooth operation and maintains food safety standards.

How Do I Identify if a Lubricant Is Truly Food-Safe?

Think of verifying a lubricant like reading a map before a journey. You look for ingredient transparency and certification labels to guarantee you’re on the right path. To identify if a lubricant is truly food-safe, check for clear ingredient lists and trusted certifications like NSF H1 or FDA compliance. These signs guarantee the product meets safety standards, so you can confidently use it on grinder threads without worries.

What Are the Signs That My Lubricant Needs to Be Replaced?

You’ll know your lubricant needs replacing when you notice signs of degradation, like changes in texture, color, or smell. Contamination detection is key—if you see dirt, debris, or unusual buildup, it’s time to substitute it. Regularly inspecting your lubricant ensures it stays effective and safe for food contact. Don’t ignore these signs; fresh lubricant keeps your grinder functioning smoothly and prevents contamination.

Conclusion

Choosing the right food-safe lubricant for grinder threads ensures safety and efficiency. Look for options with FDA approval and food-grade certifications. Did you know that the food industry’s demand for food-safe lubricants has increased by over 30% in the past five years? By selecting the correct lubricant and applying it properly, you protect both your equipment and your customers. Prioritize safety, follow regulatory standards, and keep your grinder running smoothly for ideal results.