Choosing between used and new machines depends on your long-term savings goals. Used equipment has a lower upfront cost but might lead to higher repair expenses and less reliability. New machines cost more initially but offer better technology, warranties, and efficiency, potentially reducing future costs. Balancing immediate budget constraints with future savings is key. To find out how to maximize your investment and make the smartest choice, there’s more valuable details ahead.

Key Takeaways

- Used machines are cheaper upfront but may incur higher repair and maintenance costs over time.

- New equipment offers manufacturer warranties and better support, reducing unexpected repair expenses.

- Reliability and technology are generally superior in new machines, leading to increased efficiency and safety.

- Long-term savings favor new machines due to lower maintenance costs and longer lifespan.

- Initial savings from used machines can be offset by higher operational costs and reduced productivity.

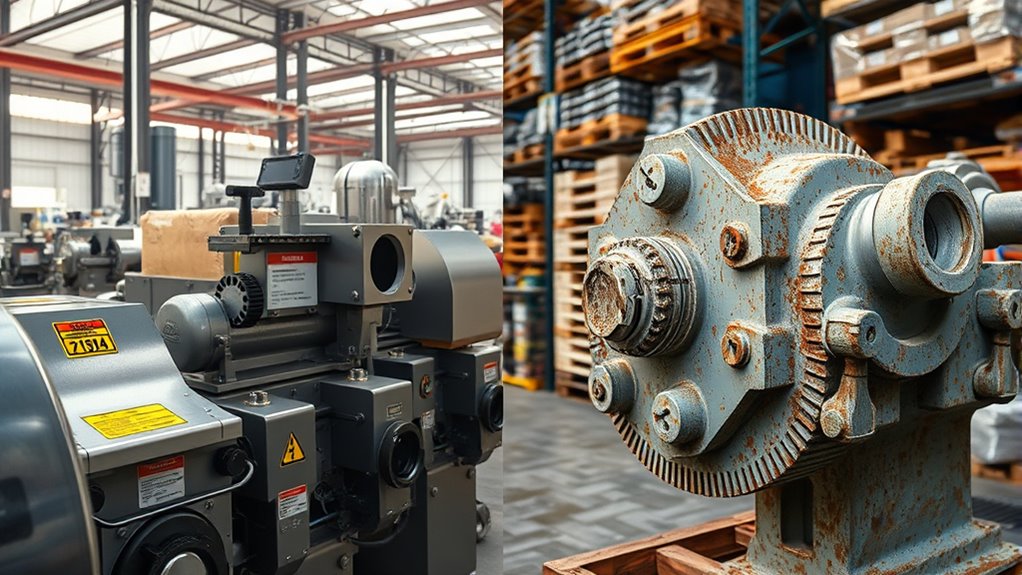

When deciding between buying used or new machines, you need to weigh factors like cost, reliability, and long-term value. One of the most immediate considerations is the cost comparison. Generally, used machines come with a considerably lower upfront price, which appeals if you’re working within a tight budget or want to conserve capital. However, it’s vital to consider that cheaper isn’t always better in the long run. Cheaper used equipment might require more repairs and maintenance, potentially increasing your overall expenses. On the other hand, new machines tend to have a higher initial cost but often include the latest technology and improvements, which can boost productivity and efficiency over time.

Used machines cost less upfront but may incur higher maintenance over time.

Warranty options play a vital role in your decision-making process. New machines typically come with extensive warranties from the manufacturer, covering parts and labor for a set period. This coverage can save you money on repairs and give peace of mind, especially if you’re concerned about unexpected breakdowns. Used machines, however, often come with limited or no warranty unless purchased from a certified dealer who offers some form of guarantee. If you’re leaning toward a used option, you’ll want to carefully review warranty terms and consider purchasing an extended warranty or service plan to mitigate potential repair costs.

Reliability is another key factor. New machines are generally more dependable because they’re brand new and haven’t experienced prior wear and tear. They usually come with the latest safety features and technological advancements, which can improve operational stability. Used equipment’s reliability depends heavily on its age, maintenance history, and how well it’s been cared for. If you opt for used, it’s wise to get a thorough inspection and review the maintenance records to ensure you’re not inheriting hidden problems. Additionally, advances in AI technology are increasingly being integrated into new machinery, offering potential improvements in efficiency and automation that used models may lack. Furthermore, technological advancements in new equipment often mean better compatibility with future upgrades and systems. Incorporating up-to-date features can significantly enhance workflow and reduce downtime, making newer models more appealing for long-term investment.

Long-term value is where the decision becomes more nuanced. While new machines cost more upfront, their longer lifespan, lower maintenance costs, and advanced features can make them more cost-effective over time. Used machinery might save you money initially but could lead to higher operational costs, frequent repairs, or earlier replacement needs. It’s also important to consider that support hours for maintenance and repairs may be more accessible for new equipment, reducing downtime. Ultimately, your choice hinges on balancing your immediate budget constraints against anticipated longevity and operational costs.

Frequently Asked Questions

How Does Warranty Coverage Differ Between Used and New Machines?

Warranty differences between used and new machines are significant. New machines typically come with full coverage, offering peace of mind and all-encompassing protection. Used machines often have limited warranty coverage or none at all, which means you might face coverage limitations if issues arise. You should carefully review warranty terms before purchasing to understand what’s covered and any restrictions, ensuring you’re prepared for potential repairs and costs.

Are Used Machines More Prone to Hidden Damages or Defects?

Many believe used machines are more prone to hidden damages or defects, but proper inspection can minimize this risk. You should thoroughly check for inspection concerns and ask about maintenance history to identify potential issues. While repair costs might be higher if hidden damages exist, regular inspections and buying from reputable sources help you avoid costly surprises later. So, with careful scrutiny, used machines can still be a reliable choice.

What Are the Environmental Impacts of Buying Used Versus New Equipment?

When considering the environmental impacts of buying used versus new equipment, you help promote sustainable practices by choosing used items, which extend the lifespan of machinery and reduce waste. Recycling initiatives become more effective when you opt for secondhand equipment, decreasing demand for new manufacturing. This choice minimizes resource extraction, lowers carbon emissions, and supports eco-friendly habits, making your purchasing decision environmentally responsible and contributing positively to the planet’s health.

How Does Resale Value Vary Between Used and New Machines?

Resale value varies between used and new machines because of resale depreciation and market demand. When you buy new, you face steep resale depreciation, meaning the machine loses value quickly, reducing its resale worth. Used machines tend to retain more value over time if market demand remains steady. You can often get a better resale price for used equipment, especially if it’s well-maintained, making it a smart financial move.

What Financing Options Are Available for Used Versus New Machinery?

In the age of dial-up, financing options for machinery have evolved. You can choose from lease options, which often require lower upfront costs, or traditional loans with varying interest rates. For used machines, lenders may offer more flexible terms but might charge higher interest. Comparing these options helps you find the best fit, ensuring you get the equipment you need without overextending your budget.

Conclusion

Ultimately, whether you choose used or new machines depends on your needs and budget. For example, imagine buying a used CNC machine for your small workshop—you’re saving thousands but still getting reliable performance. Just like Sarah did last year, who cut costs without sacrificing quality. Weigh the pros and cons carefully, and remember, smart choices today lead to better savings tomorrow. Whatever you decide, make sure it aligns with your goals and keeps your business moving forward.