Choosing between air-cooled and water-cooled machines depends on your needs for performance, maintenance, and environment. If you want a simpler, cost-effective option with less upkeep, air-cooled systems might suit you better, especially in moderate environments. However, if you need better heat dissipation for demanding applications and can handle more complex maintenance, water-cooled systems offer superior stability. To find out which suits your setup best, keep exploring the key differences.

Key Takeaways

- Choose air-cooled for simpler, cost-effective setups with low maintenance needs and adequate cooling in moderate environments.

- Opt water-cooled if you require superior heat dissipation, stability, and performance in high-temperature or demanding applications.

- Consider initial investment: air-cooled systems are cheaper upfront, while water-cooled offers better long-term efficiency and lifespan.

- Evaluate environmental factors: air-cooled needs good ventilation and may struggle in hot or confined spaces; water-cooled is less affected.

- Assess maintenance capacity: air-cooled systems demand less upkeep; water-cooled requires regular coolant management and cleaning.

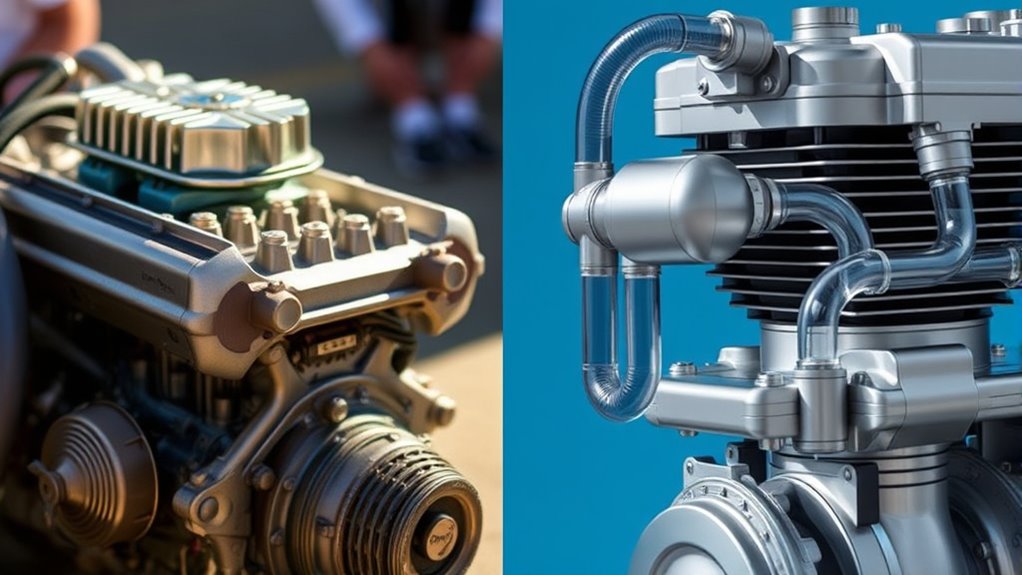

When choosing between air-cooled and water-cooled machines, understanding their differences can help you make an informed decision. Both systems have unique advantages and drawbacks, especially when it comes to cost efficiency and maintenance requirements. Your choice will depend on your specific needs, budget, and willingness to perform regular upkeep. Air-cooled machines are generally more straightforward, as they rely on fans and heat sinks to dissipate heat into the surrounding air. This simplicity often translates into lower initial costs because they don’t require complex plumbing or additional components like pumps and radiators. Over time, their cost efficiency can be appealing, especially if you’re looking to minimize ongoing expenses. However, keep in mind that air-cooled systems might struggle in hot environments or confined spaces, where heat buildup can impair performance and potentially lead to overheating. Maintenance requirements are typically less intensive for air-cooled units, since they have fewer parts that can fail or need regular cleaning. You might only need to check and replace filters or fans periodically, making them easier to manage if you prefer less hands-on upkeep. Additionally, air-cooled systems are more susceptible to environmental factors, which can influence their efficiency and lifespan. Proper ventilation and ambient temperature play a crucial role in maintaining optimal performance for these systems.

On the other hand, water-cooled machines tend to be more efficient at heat dissipation, especially in demanding applications or environments with high ambient temperatures. They use a liquid coolant circulated through a closed-loop system, which absorbs heat more effectively than air. As a result, water-cooled machines often offer better performance and stability, particularly for high-power or continuous-operation scenarios. While this setup can lead to superior cost efficiency in the long run—since better cooling can extend equipment lifespan and decrease downtime—the initial investment is usually higher. Installing a water-cooling system involves additional costs for components like radiators, pumps, and coolant, along with more complex plumbing. Maintenance requirements are also more involved; you’ll need to regularly check coolant levels, clean components to prevent bacterial growth or corrosion, and occasionally replace parts. If you prefer a low-maintenance setup or have limited technical skills, water cooling might seem less appealing despite its performance benefits. Proper maintenance of coolant quality is vital to ensure optimal operation and prevent damage to the system. Understanding the specific cooling needs of your application can help you determine whether the efficiency gains outweigh the added complexity.

Frequently Asked Questions

Which Cooling System Is More Energy-Efficient?

When considering which cooling system is more energy-efficient, you should look at thermal efficiency and environmental impact. Water-cooled systems generally offer higher thermal efficiency because they transfer heat more effectively, reducing energy use. They also tend to have a lower environmental impact due to less energy consumption. Air-cooled systems might be less efficient but are easier to maintain and better suited for smaller or less demanding applications.

How Do Maintenance Requirements Differ Between Systems?

Think of maintenance like tending a garden; both systems need regular care. Water-cooled machines often require more frequent filter changes and coolant checks, making them a bit more high-maintenance. Air-cooled systems generally need less attention, mainly lubrication and cleaning of fins. You’ll want to monitor lubrication needs and filter maintenance closely to keep either system running smoothly and prevent costly breakdowns.

Are Water-Cooled Machines More Durable Than Air-Cooled Ones?

Water-cooled machines often last longer because the cooling fluid efficiently manages heat dissipation, reducing stress on components. This means they’re generally more durable, especially in high-performance settings. However, you need to contemplate maintenance of the cooling fluid and potential leaks. Air-cooled systems are simpler but might experience more wear over time due to less effective heat dissipation. Your choice depends on your environment and maintenance willingness.

What Is the Initial Cost Comparison?

While water-cooled machines might seem like a splurge, their higher initial cost reflects advanced technology and better long-term performance. You’ll find the cost difference can be significant, making budget considerations key. Air-cooled systems generally cost less upfront, fitting tighter budgets. If you prioritize lower initial expenses, air-cooled options could be more suitable. However, weigh the long-term benefits to determine which investment aligns best with your financial plan.

Which System Performs Better in Extreme Temperatures?

In extreme temperatures, your choice impacts thermal regulation and environmental impact. Water-cooled systems generally perform better, maintaining stable temperatures and preventing overheating, especially in hot conditions. They often have more precise thermal regulation, which can boost efficiency and equipment lifespan. However, they might have a higher environmental impact due to water use. Air-cooled systems are simpler and less water-dependent but may struggle with consistent cooling in extreme heat.

Conclusion

Ultimately, choosing between air-cooled and water-cooled machines depends on your specific needs and environment. Do you prioritize simplicity and lower upfront costs, or do you need maximum performance and efficiency? Both options have their merits, so consider your workload, space, and budget carefully. By weighing these factors, you can make an informed decision that keeps your machine running smoothly. After all, isn’t investing in the right cooling system essential for long-term success?